SERVICES

Prevent failures • Solve problems • Maximize uptime

At Resof, our Technical Services go beyond fixing problems — we prevent them. From advanced predictive maintenance to expert corrective interventions, we help your refrigeration systems perform at their best, minimize downtime, and stay one step ahead of failure. Backed by certified specialists, cutting-edge tools, and 25+ years of experience.

Inspection & Calibration

We ensure your system’s key sensors and components are precisely calibrated to operate within the correct parameters — avoiding performance drifts and costly inefficiencies.

Laser Alignment

Misaligned shafts in rotating machinery can cause excessive vibration, energy loss, and premature wear. Our laser alignment service corrects these deviations with high accuracy — increasing efficiency and preventing costly breakdowns.

Mechanical Vibration

Hidden imbalances and looseness in mechanical systems often go unnoticed — until they cause serious damage. Our vibration analysis identifies these issues early, allowing you to act before a failure occurs.

Thermography

Our thermographic inspections use infrared technology to evaluate the condition of mechanical and electrical components — based on the heat they emit during operation. This non-invasive test reveals early signs of failure that are invisible to the naked eye.

Oil Analysis

Oil is the lifeblood of your refrigeration system — and analyzing it gives us a direct look at the health of your equipment. Our oil analysis detects early signs of wear, contamination, and system degradation that could lead to costly failures if left unchecked.

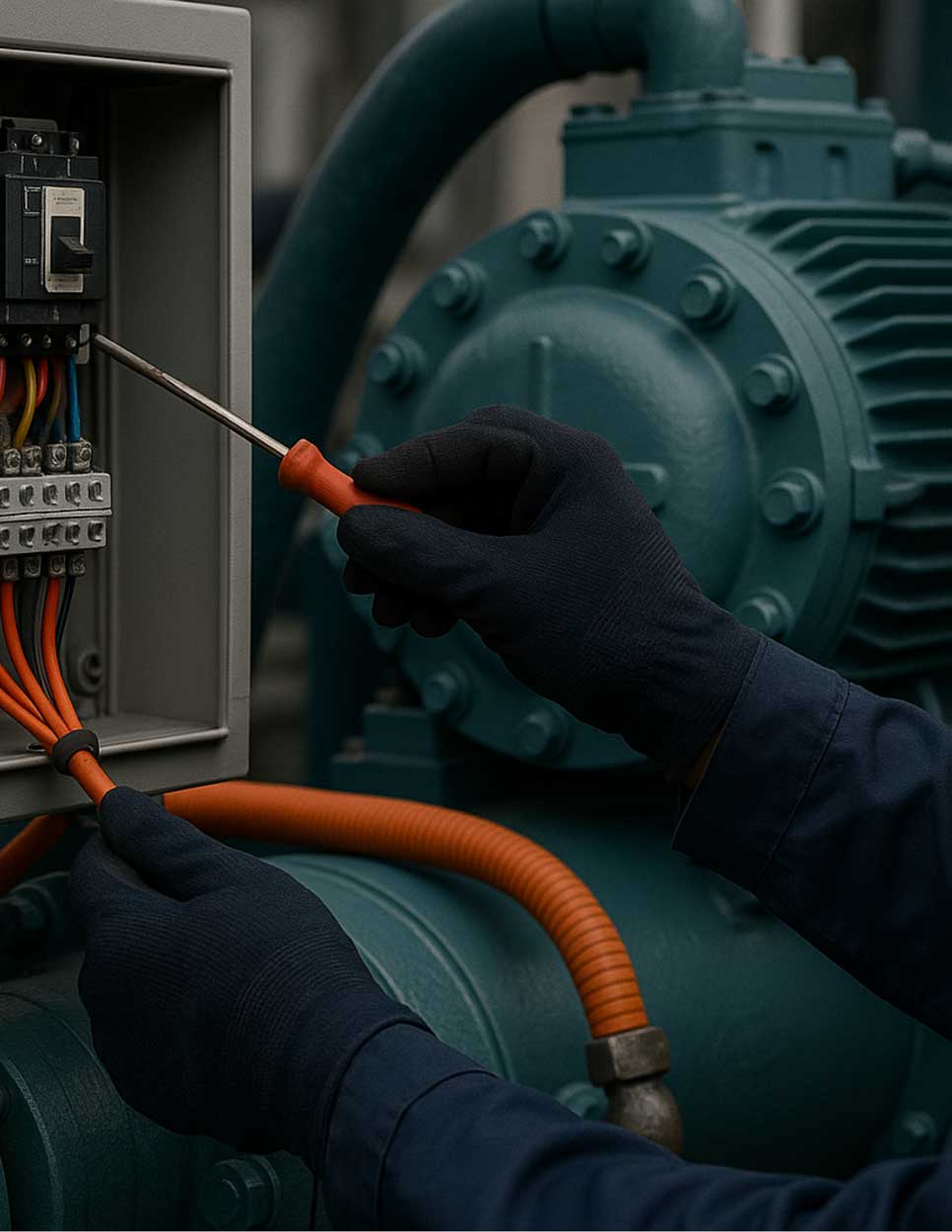

Technical Support

Even with the best maintenance practices, unexpected issues can still arise — and when they do, Resof is ready. Our Corrective Services are designed to provide fast, reliable, and effective solutions to restore your industrial refrigeration systems and keep operations running with minimal disruption.